At the celebration ceremony of the new nuclear powered aircraft carrier of the US Navy and the American hero after whom the ship is named, Huntington Ingalls Industries’ christened the John F. Kennedy (CVN 79) at the Newport News Shipbuilding division of the company. Newport News Shipbuilding division.

“We are here to celebrate America’s military might and the brawn behind it,” said Jennifer Boykin, president of Newport News Shipbuilding. “We are here to celebrate innovation, pride and perseverance that is the American way, and we are here to honor the patriot who inspired it. I speak for every Newport News shipbuilder — 25,000 strong — and the thousands of suppliers across the nation who support us when I say that we are proud to build John F. Kennedy.”

A a bottle of American sparkling wine was smashed across the bow by the former U.S. ambassador Caroline Kennedy, the ship’s sponsor and daughter of President Kennedy to christen the ship. In her speech she also mentioned about christening the first aircraft carrier that is named after her father.

“This ship will represent the ideals he lived by – courage, sacrifice and belief in freedom – and it will help make real his vision of a more just America and a more peaceful world,” Kennedy said. “I’m so proud to be sponsor of this ship and to join with all of you to bring her to life. I look forward to being part of her odyssey and of her extended family. Most of all, I hope she will carry my father’s spirit with her as she sails, his leadership in wartime, his courage in crisis and his commitment to the hard and steady work of building peace.”

The ceremony was attended by over 20,000 including members of the Virginia congressional delegation U.S. Sen. Mark Warner and U.S. Rep. Robert C. Scott, who both offered remarks; and U.S. Rep. Elaine Luria. Other speakers included former U.S. Secretary of State John Kerry and Adm. Frank Caldwell, director of the Naval Nuclear Propulsion Program.

James Geurts, assistant secretary of the Navy for research, development and acquisition; Vice Adm. Thomas Moore, commander of Naval Sea Systems Command (NAVSEA); Adm. Christopher W. Grady, commander of U.S. Fleet Forces Command; and Capt. Todd Marzano, the ship’s prospective commanding officer also participated in the ceremony.

Adm. Tom Fargo (U.S. Navy, Ret.), HII chairman of the board, and Mike Petters, HII president and CEO, were in attendance along with the employees of Newport who are building Kennedy, Kennedy’s crew, Navy personnel and other government officials. The ceremony was also attended by former sailors who served on the first USS John F. Kennedy (CV 67) that was built and christened at Newport News in May 1967.

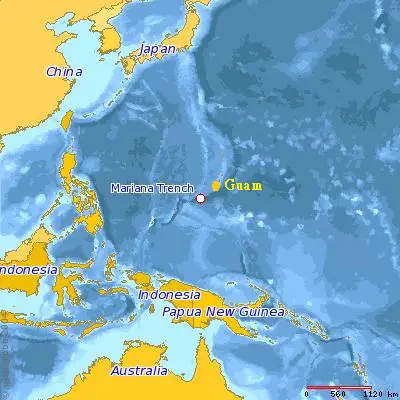

“As we observe ‘a date which will live in infamy’ on this 78th anniversary of the Japanese attack on Pearl Harbor, this magnificent vessel we see before us today is a symbol of our nation’s strength, of our technical achievements and of the critical service our men and women in uniform provide for this nation and the entire world,” said Charles Frank Bolden Jr., a retired U.S. Marine Corps major general and former NASA administrator, and astronaut who served as the principal speaker. “This carrier is also a tangible example of the legacy of a great man who risked his own life volunteering for hazardous duty in the Pacific during World War II in the wake of Pearl Harbor, and later came to embody a time of optimism that he translated into a vision for taking humans beyond the sphere of our planet.”

Since February 2011, when the construction of ship started, over 5,000 shipbuilders have helped in Kennedy’s construction and suppliers from 46 states in the country have provided with specialized parts, skilled services and support to aircraft carrier production. After christening, the vessel will be introduced in the James River and then moved to a pier where the ship’s outfitting and testing will be done. It is scheduled to be delivered to the U.S. Navy in 2022.

“President John F. Kennedy taught us that deterrence will always cost less than war,” said Thomas Modly, acting Secretary of the Navy. “The purpose of our military, including this warship that bears his name, must be to ensure our nation’s commitment to peace and prosperity for all nations of the world.”

Reference: huntingtoningalls

from WordPress https://www.maritimemanual.com/hii-christens-us-navys-newbuild-nuclear-powered-aircraft-carrier-john-f-kennedy/